Certifications

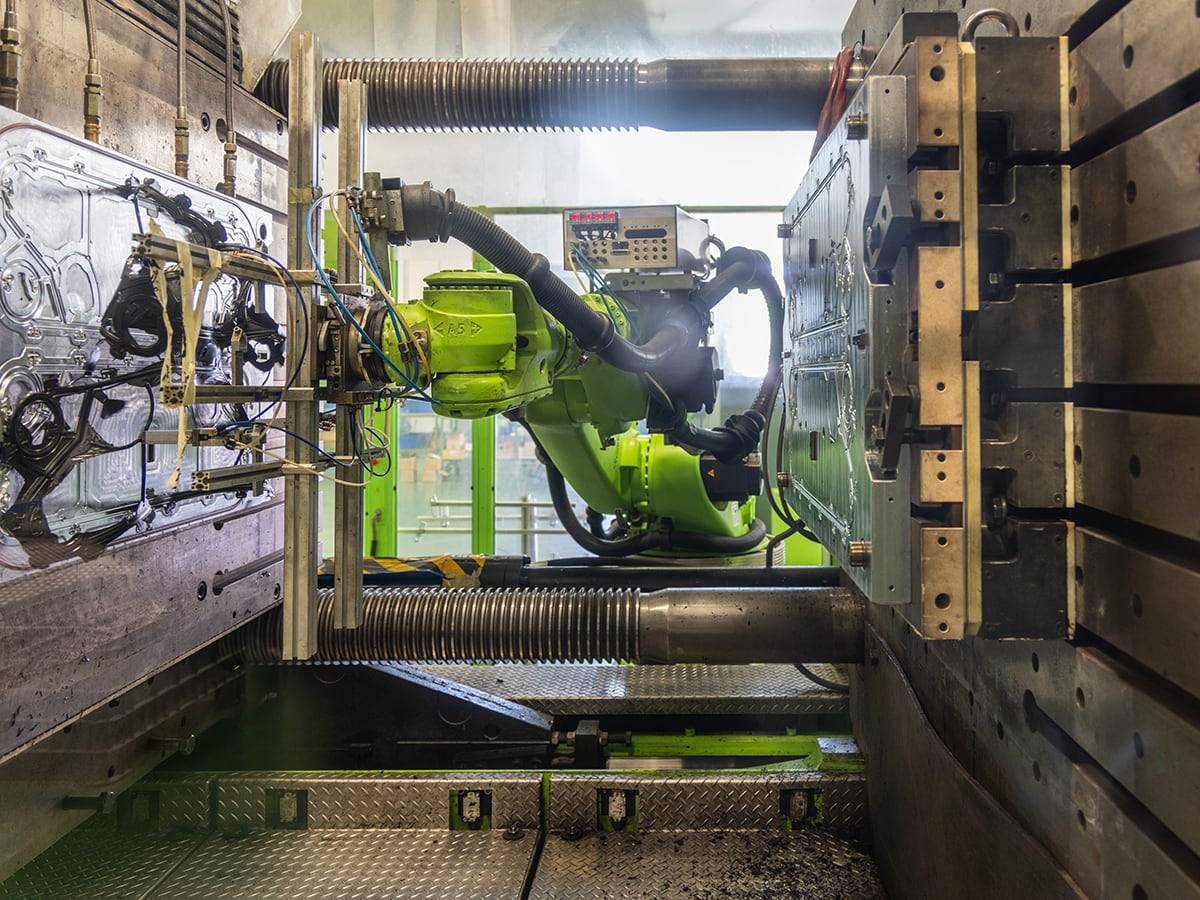

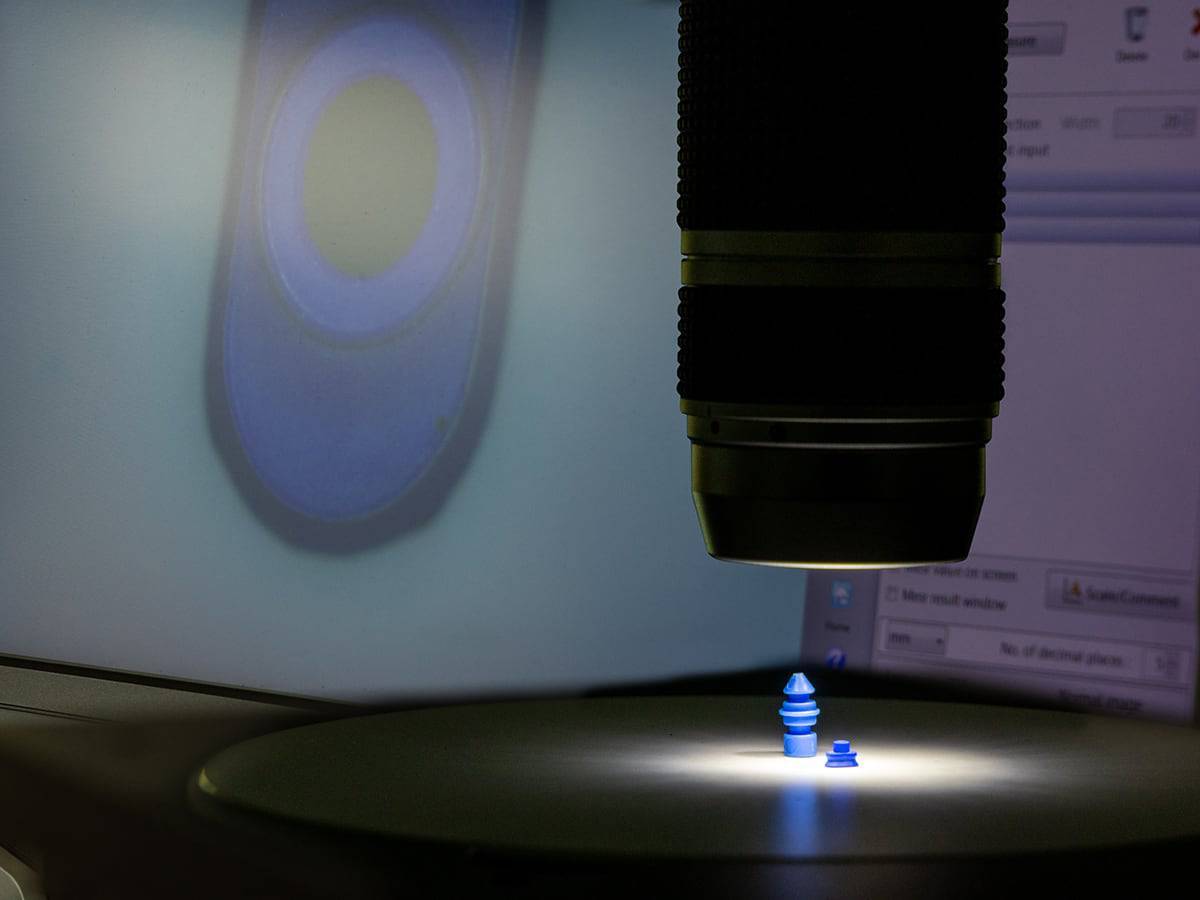

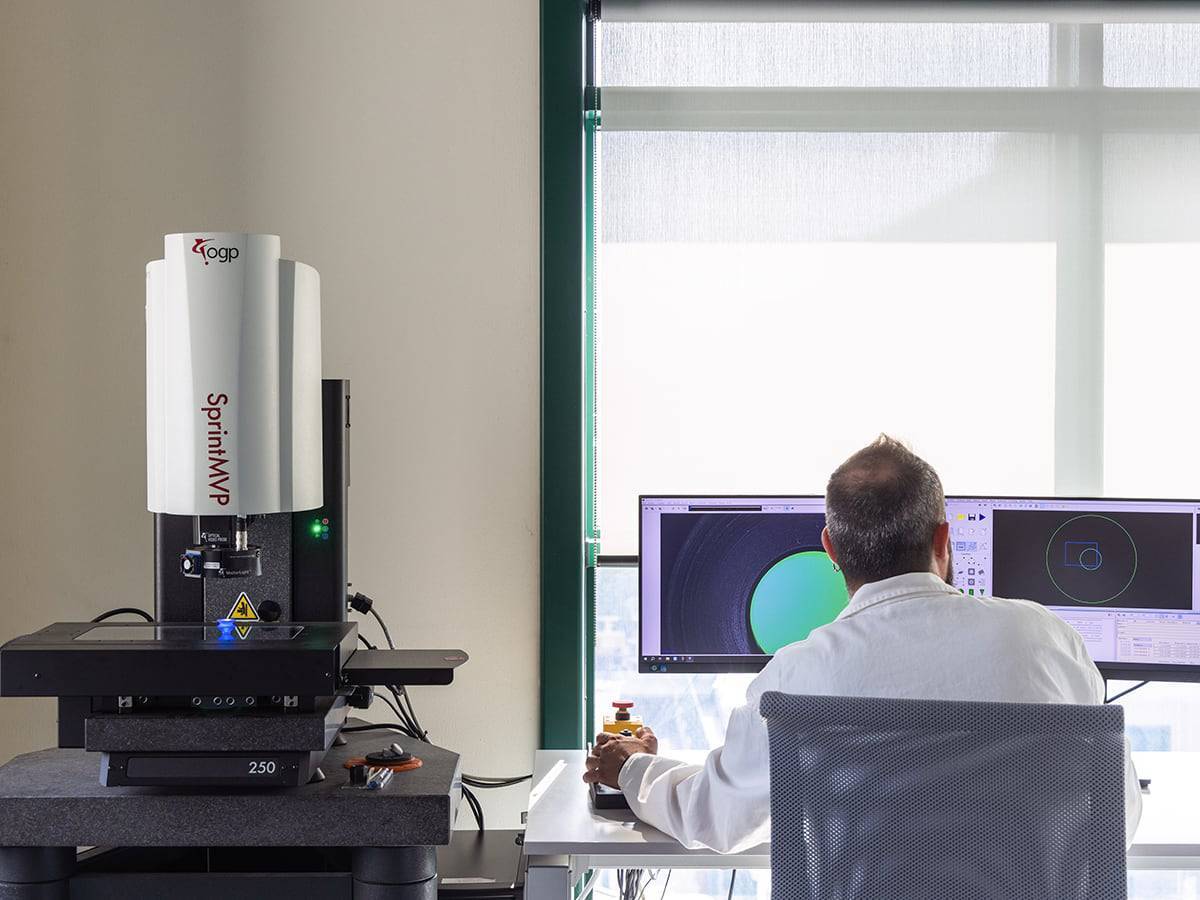

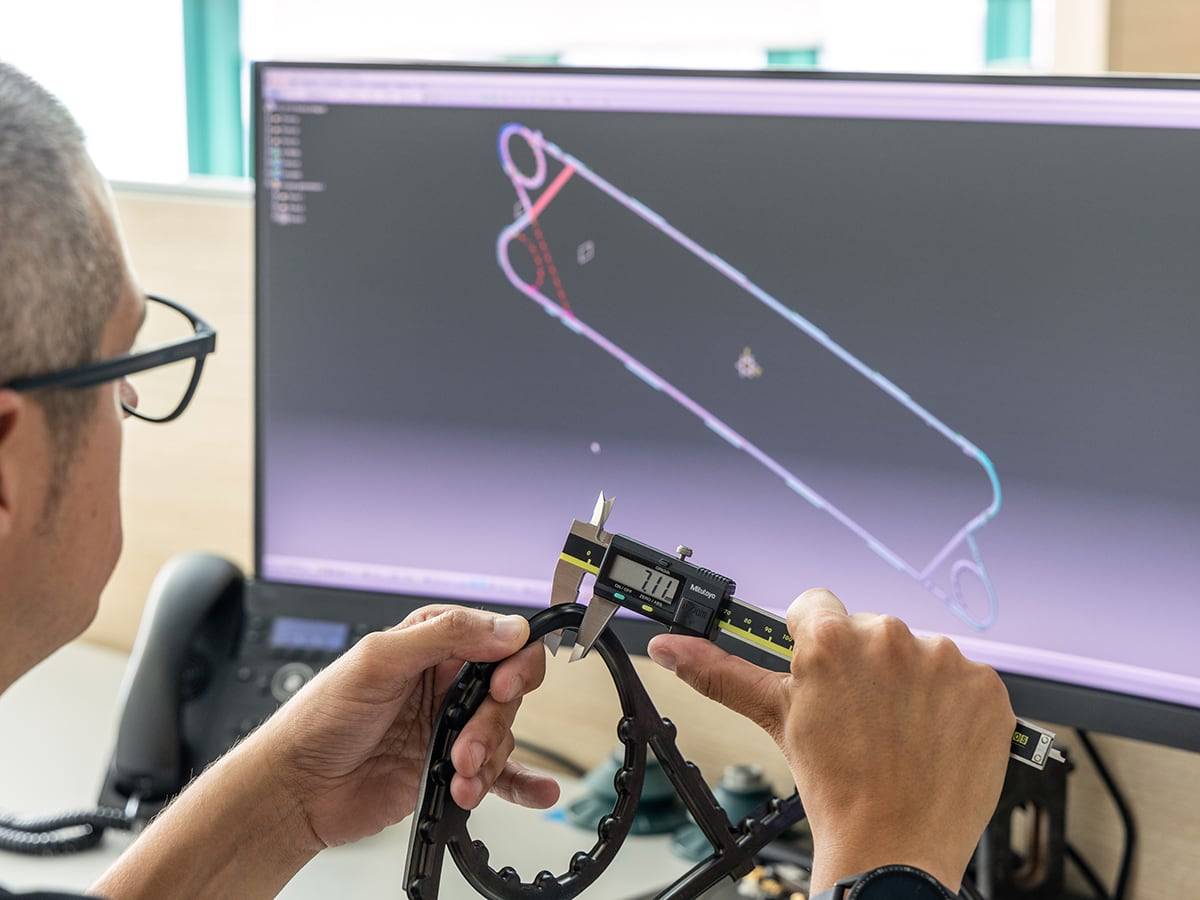

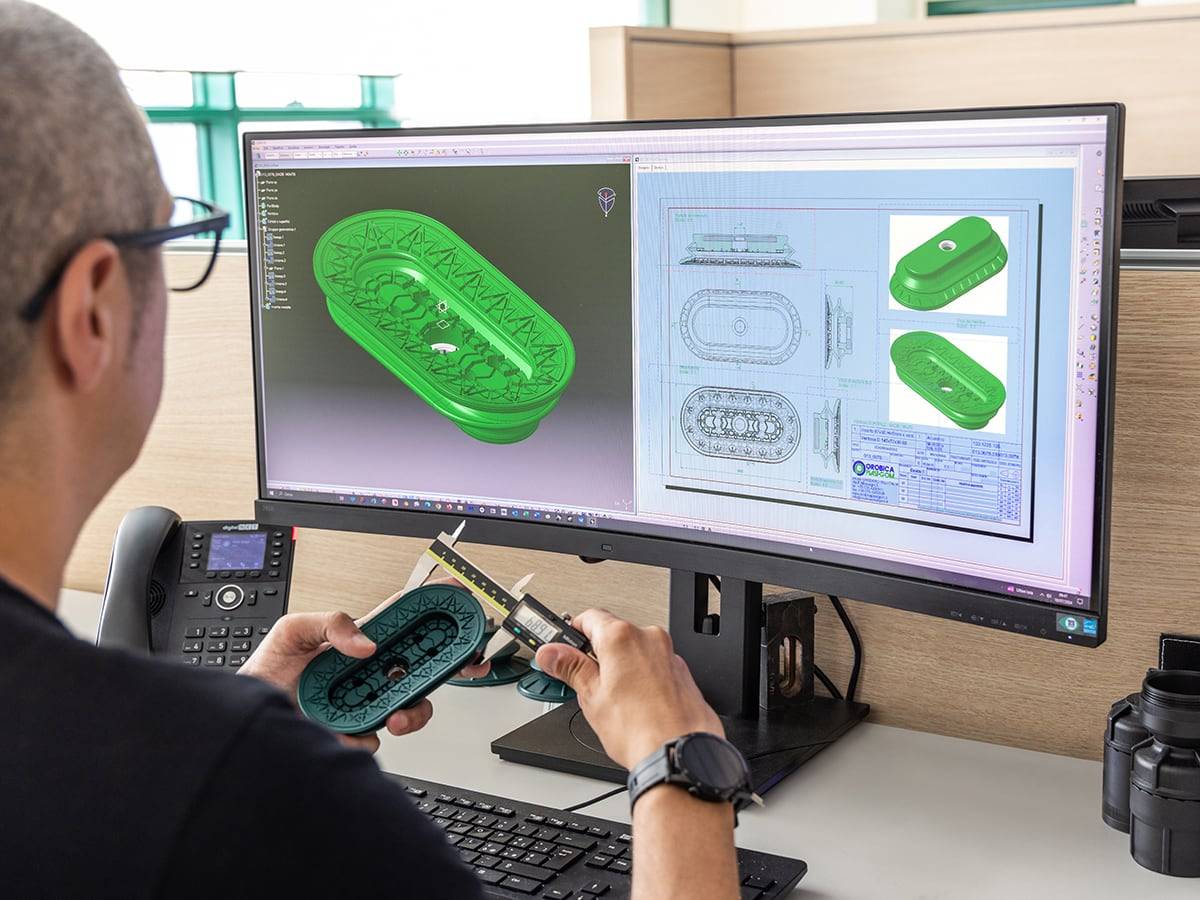

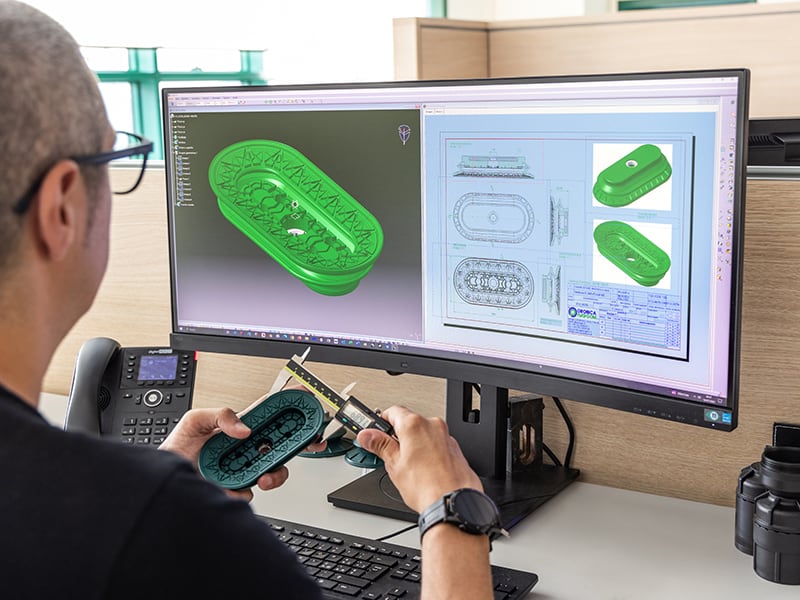

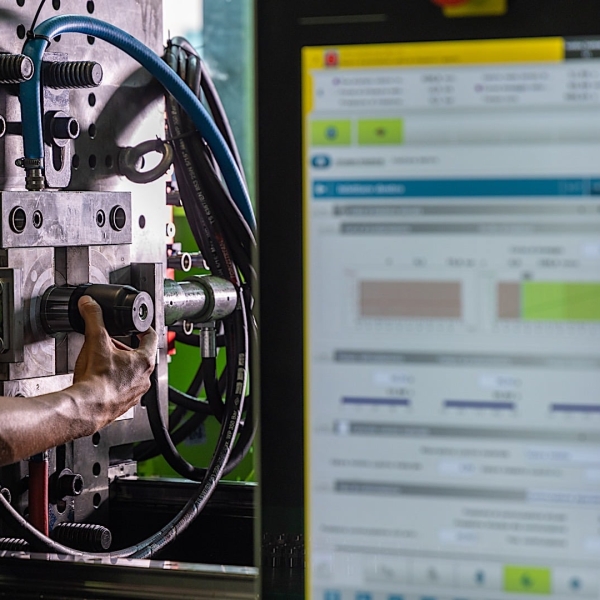

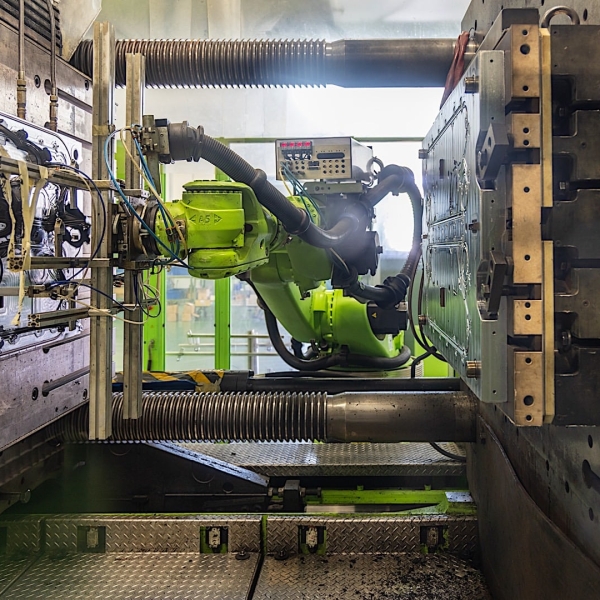

Every Orobica Plast-Gom product—whether suction cup, gasket, membrane, or custom item—is carefully monitored throughout its life cycle: from design and material selection to processing and quality control.

We are certified according to UNI EN ISO 9001 and UNI EN ISO 14001.

For food-contact applications:

- FDA, KTW, BfR

- EN 1935/2004

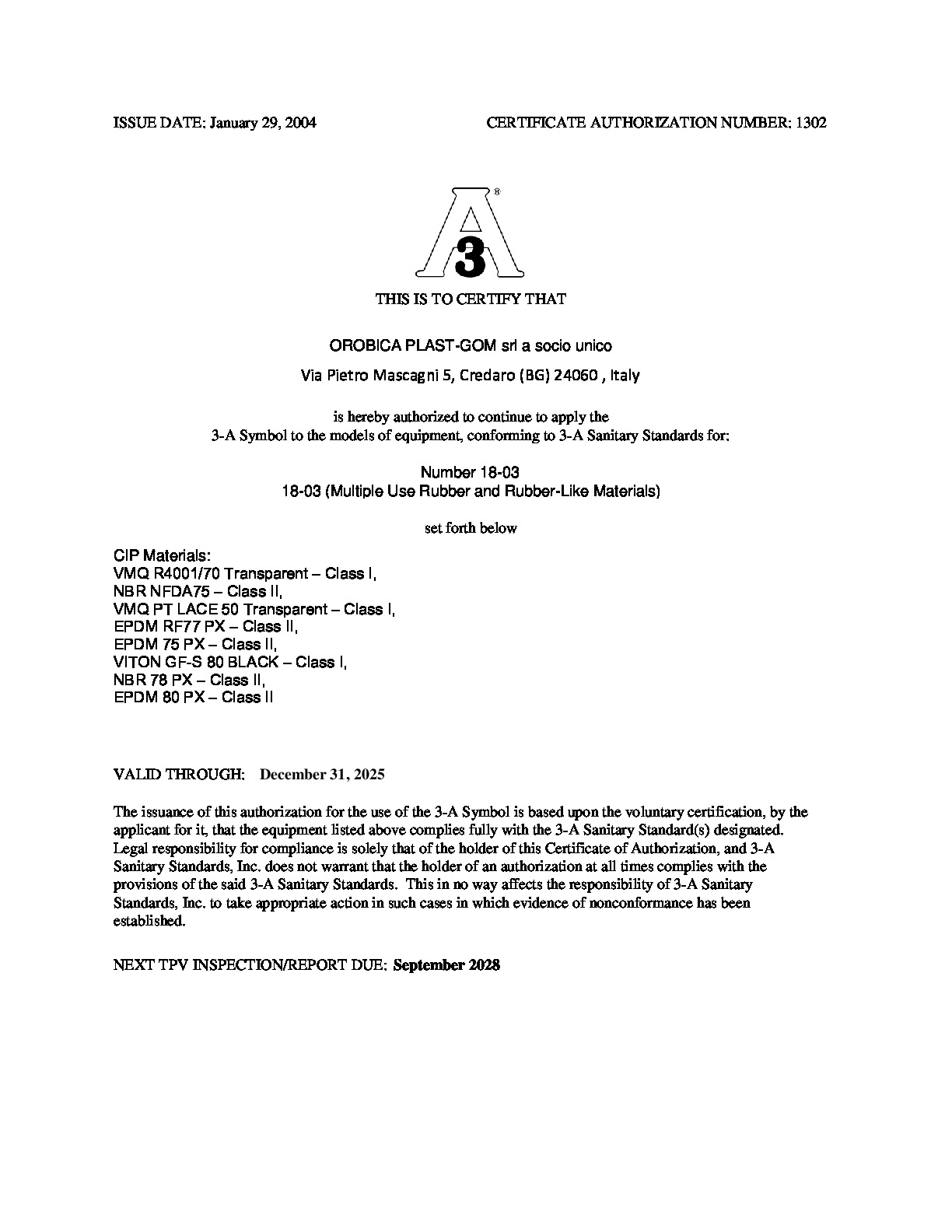

- 3-A Sanitary Standard

- French Arrêté

- CE 2023/2006 GMP compliance for manufacturing materials in contact with food

For pharmaceutical applications:

- USP Class VI

For nuclear applications:

- EDF standard compliance

Our rigorous production methods, paired with continuous research and supplier partnerships, enable consistently high standards.

Application fields

Bottling and Packaging

Food and Beverage Industry

Pharmaceutical Industry

Biofuels

Chemicals, Steelworks, and Marine

Dairy Processing

Paper and Pulp

Glass, Wood, Sheet Metal, Ceramics, Marble

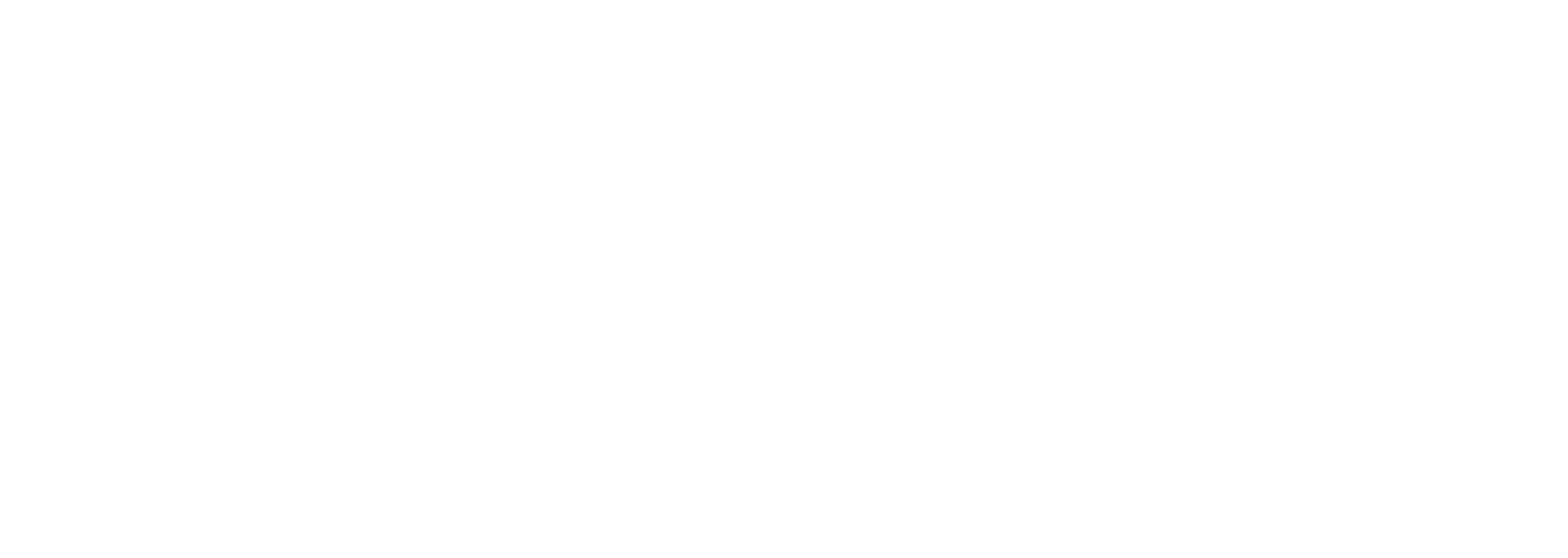

Automation, Robotics, and Vacuum Systems

Energy and Nuclear Power

HVAC (Heating, Ventilation, and Air Conditioning)

Automotive and Molding

Our Numbers speak

of all-Italian quality

of all-Italian quality

1980

Founded as a component supplier for the bottling sector, then expanded into packaging, food, wood, glass, and marble industries.

1985

Began design and distribution of vacuum suction cups in various formats for packaging, automation, and robotics.

1995

Doubled production facilities and warehouses. Started designing plate heat exchanger gaskets.

2002

Opened a subsidiary in Curitiba, Brazil, to serve South American markets.

2010

Moved into a new 10,000 m² industrial hub. Established RM Service for heat exchanger maintenance and spare parts.

2013

Acquired Gamavuoto, leader in vacuum products.

2015

Founded Flexilis, specialists in custom technical items in elastomers and thermoplastics.

2016

Opened Orobica New Zealand Ltd.

2017

Launched Gamavuoto Germany to strengthen European presence.

2019

Acquired Regro, Italian mold manufacturer for thermoplastics.